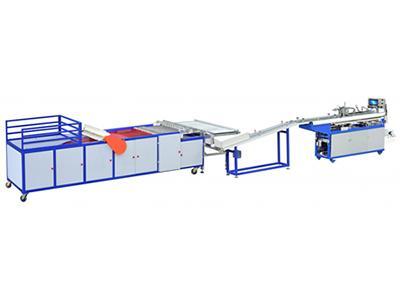

Cam Servo Motor Cup Making Machine

Application

The cam servo motor cup making machine is used primarily to form the plastic sheet. The machine uses a transmission structure of the cam plus servo motor in order to meet fully mechanical power to make operation stable, reliable, and convenient. Maintenance is also easy and convenient.

The maximum formed area of this cam servo motor cup making machine is 750 x 450mm, with the machine capable of manufacturing different plastic one-off bowls, drinking cups, ice cream cups, jelly cups and other packing containers. Primary materials include PP, PE, PS, PET, HIPS, PVC and other degradable materials.

Production technique

This cam servo motor cup making machine consists of sheet loader, the main machine, winding frame and electrical control cabinet.

The process includes:

Sheet loading → Heating → Stretch forming → Cutting → Finished product blowing

| Model | |

| Main Motor Power | 15kw |

| Formed Area | ≤750 x 450mm |

| Formed Depth | ≤180mm |

| Formed Speed | ≤35time/min |

| Sheet Width | ≤750mm (adjustable) |

| Sheet Thickness | 0.2-2.5mm |

| Machine Power | ≤110kw (the actual is about 70%) |

| Air Pressure | ≤0.6-0.8Mpa |

| Gas Consumption | 3.0-3.5m³/min |

| Water Consumption | ≤0.5m³/24h |

| Size (L x W x H) | 4.3 x 1.6 x 2.6m |

Features

1. With a cam plus servo motor transmission structure, the cup making machine has a low operating noise, and a clean, pollution free operation.

2. Using a four column structure, the mold forming platform runs in a stable, precise manner.

3. This machine is formed using a servo stretch, which makes it powerful and more suited to processing thicker sheets and making longer cups.

4. This machine uses a chain retreat device to make it convenient and safe to exchange the molds.

5. The entire machine is digitally controlled using a PLC industrial computer.

Technical support

1. Elite Machinery offers custom molds for customers according to the plastic products your company will be producing.

2. The entire machine design meets international safety standards, and a CE certificate will be supplied upon request.

3. This cam servo motor cup making equipment can be modified to meet specific customer needs, and we have a senior engineer on hand to offer professional reference advice.

4. This cam servo motor cup making machine is easy to maintain, and our professional technician can come to your factory to debug, install, train and guide, as well as offer related after-sales service.

5. The warranty period for the machine is one year, with electrical components covered for 6 months.

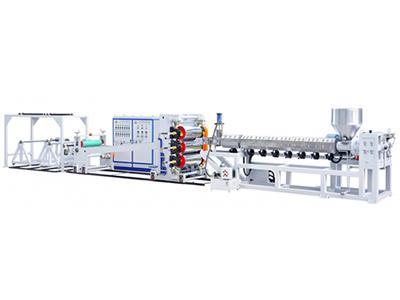

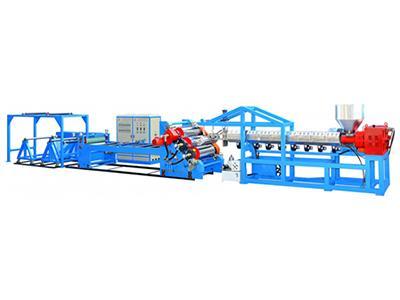

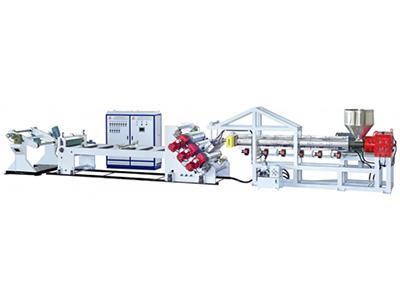

ELITE Plastics is manufacturing plastic forming and sheet extrusion equipment, such as sheet extrusion line for various plastic materials like PE, PPT, PS, PET, etc. and offers the custom thermoplastic machines and thermoforming equipment and other plastic thermoforming machines. With almost 20 years experiences of manufacturing plastic machines, ELITE Plastics can provide any client good plastic thermoplastic and extrusion machines.

Index

plastic cup forming machine, polypropylene cup, polyethylene cup, polystyrene cup making machine, HIPS cup machine

Shantou Elite Machinery Co., Ltd.

Add.: A1 Building in Baoyuan Industry Zone, Jinping District, Shantou City, Guangdong Province, China

Contact:

Tel: +86-754-88108038